ERP for the Automotive Industry In today’s fast-paced and ever-evolving business environment, staying competitive is a constant challenge. One of the most effective tools to achieve this is through the implementation of Enterprise Resource Planning (ERP) systems. These systems have revolutionized various industries, and the automotive sector is no exception. But what exactly is ERP, and why is it so crucial for the automotive industry?

Understanding the Automotive Industry

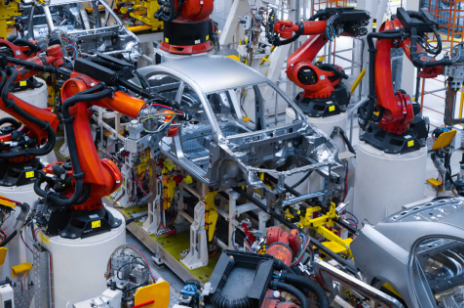

The automotive industry is a vast and complex sector encompassing everything from the design and manufacturing of vehicles to their marketing and sales. It includes a diverse range of companies and organizations involved in the development, production, and selling of motor vehicles. The industry faces numerous challenges, such as managing a vast supply chain, ensuring quality control, meeting regulatory compliance, and addressing fluctuating market demands.

What is ERP?

ERP stands for Enterprise Resource Planning. It is a type of software that organizations use to manage and integrate the important parts of their businesses. An ERP software system can integrate planning, purchasing inventory, sales, marketing, finance, human resources, and more. Essentially, ERP systems bring together all the facets of an operation into a single, cohesive system.

Why the Automotive Industry Needs ERP

Streamlining Operations

ERP systems help streamline various business processes by automating and integrating them into a single, unified system. This ensures that information flows seamlessly across different departments, reducing redundancies and increasing efficiency.

Enhancing Productivity

With ERP systems, automotive companies can significantly enhance their productivity. The automation of routine tasks means employees can focus on more strategic activities, thus increasing overall productivity.

Reducing Costs

By optimizing resources and improving process efficiency, ERP systems help automotive companies reduce operational costs. They provide better visibility into the company’s operations, which allows for more informed decision-making and cost-saving strategies.

Core Features of ERP Systems for Automotive Industry

Inventory Management

Effective inventory management is crucial in the automotive industry. ERP systems provide real-time inventory tracking, which helps in maintaining optimal stock levels, reducing excess inventory, and minimizing stockouts.

Supply Chain Management

ERP systems enhance supply chain management by providing real-time visibility into supply chain operations. This ensures timely procurement of raw materials, efficient production planning, and timely delivery of finished products.

Production Planning

ERP systems assist in efficient production planning by integrating all production-related activities. This includes scheduling, resource allocation, and workflow management, ensuring that production processes are optimized for maximum efficiency.

Quality Control

Maintaining high quality is essential in the automotive industry. ERP systems provide tools for monitoring and controlling the quality of products at every stage of production, ensuring that the final product meets the required standards.

Financial Management

ERP systems offer comprehensive financial management tools, including accounting, budgeting, and financial reporting. This helps automotive companies manage their finances more effectively and make better financial decisions.

Benefits of ERP in the Automotive Industry

Improved Efficiency

ERP systems improve overall efficiency by automating various business processes and providing real-time access to critical information. This allows for quicker response times and better coordination among departments.

Better Decision-Making

With real-time data and advanced analytics, ERP systems provide valuable insights that aid in better decision-making. Automotive companies can make more informed decisions regarding production, inventory, and supply chain management.

Enhanced Customer Satisfaction

By streamlining operations and improving efficiency, ERP systems help automotive companies deliver better products and services to their customers. This leads to higher customer satisfaction and loyalty.

Real-Time Information Access

ERP systems provide real-time access to critical business information. This enables automotive companies to respond quickly to market changes and customer demands, ensuring that they stay ahead of the competition.

Implementing ERP in the Automotive Industry

Steps to Implement ERP

- Needs Assessment: Identify the specific needs of the company and what they aim to achieve with an ERP system.

- Choosing the Right ERP: Select an ERP system that aligns with the company’s requirements and goals.

- Planning: Develop a detailed implementation plan, including timelines, resources, and budget.

- Customization: Customize the ERP system to fit the unique needs of the company.

- Training: Provide comprehensive training to employees to ensure they can effectively use the ERP system.

- Deployment: Roll out the ERP system in phases to ensure a smooth transition.

- Evaluation: Continuously monitor the system’s performance and make necessary adjustments.

Choosing the Right ERP System

Selecting the right ERP system is crucial for a successful implementation. Automotive companies should consider factors such as scalability, ease of use, integration capabilities, and vendor support when choosing an ERP system.

Common Challenges in ERP Implementation

Implementing an ERP system can be challenging. Common challenges include resistance to change, inadequate training, data migration issues, and lack of proper planning. Addressing these challenges proactively is key to a successful implementation.

Case Studies

Success Stories of ERP in Automotive Companies

Several automotive companies have successfully implemented ERP systems and reaped significant benefits. For instance, a major automotive manufacturer streamlined its supply chain operations and reduced costs by implementing an ERP system. Another company improved its production planning and enhanced product quality through ERP.

Lessons Learned from ERP Failures

Not all ERP implementations are successful. Lessons learned from failures include the importance of thorough planning, involving all stakeholders, providing adequate training, and choosing the right ERP system.

Future Trends in ERP for the Automotive Industry

Integration with IoT

The integration of ERP systems with the Internet of Things (IoT) is a growing trend. This allows for real-time monitoring and data collection from connected devices, providing valuable insights and improving operational efficiency.

AI and Machine Learning in ERP

Artificial intelligence (AI) and machine learning are increasingly being integrated into ERP systems. These technologies enable predictive analytics, automate routine tasks, and enhance decision-making capabilities.

Cloud-Based ERP Solutions

Cloud-based ERP solutions offer several advantages, including lower upfront costs, scalability, and ease of access. More automotive companies are adopting cloud-based ERP systems to stay agile and competitive.

Conclusion

ERP systems play a critical role in the automotive industry by streamlining operations, enhancing productivity, and reducing costs. With the integration of advanced technologies like IoT, AI, and cloud computing, the future of ERP in the automotive industry looks promising. By adopting ERP systems, automotive companies can improve efficiency, make better decisions, and ultimately enhance customer satisfaction.

FAQs

What is ERP?

ERP stands for Enterprise Resource Planning. It is software that integrates various business processes and functions into a single system.

How does ERP benefit the automotive industry?

ERP systems streamline operations, enhance productivity, reduce costs, and provide real-time access to critical information, helping automotive companies stay competitive.

What are the key features to look for in an automotive ERP system?

Key features include inventory management, supply chain management, production planning, quality control, and financial management.

Can small automotive companies benefit from ERP?

Yes, ERP systems can benefit small automotive companies by improving efficiency, reducing costs, and providing valuable insights for better decision-making.

How long does it take to implement ERP in the automotive industry?

The implementation time can vary depending on the company’s size and complexity. It typically takes several months to a year for full implementation.